Main menu

You are here

Build a house - Earth Work (Soil test - Shoring and Dewatering )

Earth Work

Earth Work

- Soil test

- Shoring and Dewatering

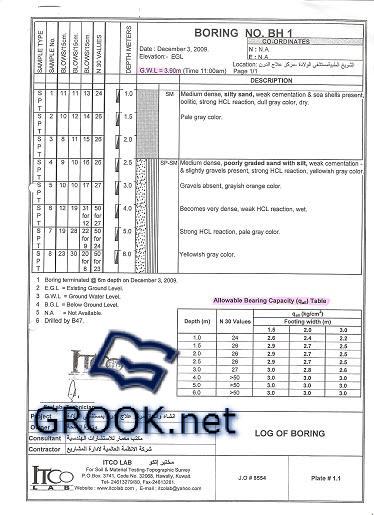

Soil Test

Alot of information result from Soil test so soil test report help us to know:

Type of soil which help us to choice suitable footing type.

Allowable Bearing Capacity which help us to design footings.

Ground Water level : Which help us to decide if we must use dewatering or not.

Soil Test

Soil Test Report

Shoring and Dewatering

Dewatering (pronounced de-water-ing) is the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes, such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes.

Construction dewatering, unwatering, or water control are common terms used to describe removal or draining groundwater or surface water from a riverbed, construction site, caisson, or mine shaft, by pumping or evaporation. On a construction site, this dewatering may be implemented before subsurface excavation for foundations, shoring, or cellar space to lower the water table. This frequently involves the use of submersible "dewatering" pumps, centrifugal ("trash") pumps, eductors, or application of vacuum to well points.

The Contractor shall submit for approval his proposed design and detailed layout for the dewatering system or systems he intends to install. The proposed system(s) shall be designed to ensure the following:

1- The lowering of the water table over the site to allow excavation to proceed and maintaining the water level below the base of excavation as it proceeds (draw down period).

2- The reduction of piezometric levels in the underlying strata sufficiently during the draw down stage to ensure stability of the excavation.

3- Once excavation is complete the water level in the ground must be maintained, during the construction period, at least 0.50 meter below the deepest excavation level until the Engineer decides that dewatering may be stopped.

4- Restoring the water level to its initial position shall be made after the space between the face of the excavation and the basement wall is backfilled and once the weight of the structure exceeds the hydrostatic uplift. In any event, the decision as to when dewatering operations shall cease or be reduced shall be exclusively that of the Engineer.

5- That “heave” of the excavation base due to upward groundwater pressure does not occur.

6- The System(s) must run twenty-four (24) hours a day and the design shall include sufficient standby pumps connected in the system(s) so as to operate automatically in case of pump failure.

DEWATERING EQUIPMENT AND MONITORING PIEZOMETERS

Provide all necessary perimeter trenches, pipes, pumps, etc., as required for the purpose of collecting and disposing of all excess water inflow into the bottom of excavations.

Provide and maintain minimum one temporary piezometer for monitoring the water table levels on site on a daily basis during the draw down and construction phases. The location and design of the temporary piezometer shall be approved by the Engineer.

Dewatering must continue until

a) All foundation work and damp proofing has been carried out to the satisfaction of the Engineer.

b) Adequate compensation of uplift forces, increased by a suitable factor of safety has been attained.

Shoring is a general term used in construction to describe the process of supporting a structure in order to prevent collapse so that construction can proceed. The phrase can also be used as a noun to refer to the materials used in the process.

Buildings- It is used to support the beams and floors in a building while a column or wall is removed. In this situation vertical supports are used as a temporary replacement for the building columns or walls.

Trenches - During excavation, shoring systems provide safety for workers in a trench and speed excavation. In this case, shoring should not be confused with shielding. Shoring is designed to prevent collapse where shielding is only designed to protect workers when collapses occur. Concrete structures shoring, in this case also referred to as falsework, provides temporary support until the concrete becomes hard and achieves the desired strength to support loads.

.

METHOD OF SHORING

Vertical face support systems are to be designed to withstand all soil, water and surcharge pressures however arising without undue deflection or other evidence of distress. Where roads, services or other installations lie within a distance from the temporary support equal to the depth of the excavation, ground movements are to be monitored and limited to amounts agreed with the appropriate authorities.

MATERIALS

A. Structural steel used for shoring and lateral-bracing systems shall be designed in accordance with American Institute of steel Construction AISC (ASD) 89 Ninth Edition – Code of Practice for the Structural Use of Steelwork in Building.

B. Timber used for shoring and lateral bracing system shall be in accordance with BS 5268 or Code of Practice for the Structural Use of Timber.

C. Concrete used for lateral bracing system shall be in accordance with 'Building Code Requirements for Reinforced Concrete' (ACI 318-99), American Concrete Institute.

D. Tie back tendons if required shall consist of either high strength bars or groups of wire strand cables; the sizes and capacities to be proposed by the Contractor.

E. Cement grout materials and admixtures for tieback anchorage shall be proposed by the Contractor for approval of the Engineer.

Structural steel used for shoring and lateral-bracing systems

Machine to fix steel supports (coring )

Vertical support systems

Timber used for shoring and lateral bracing system

coring to fix high strength bars

Cement grout materials and admixtures for tieback anchorage

Tie back tendons